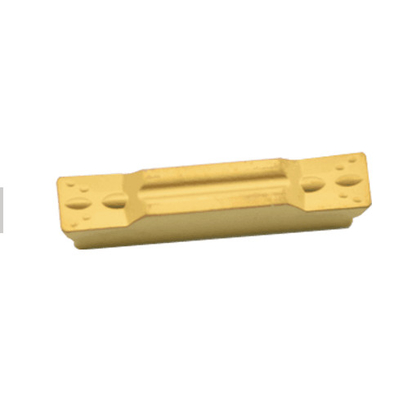

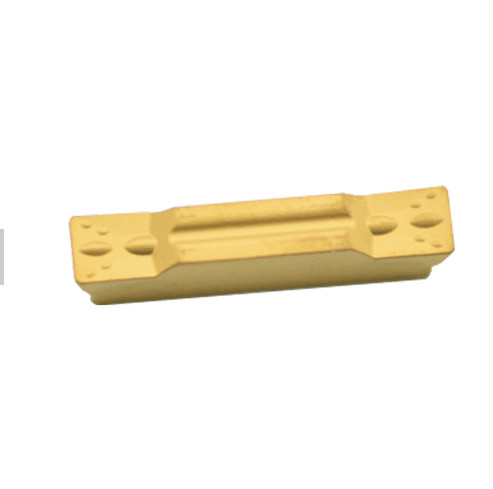

Stainless Steel Parting And Grooving Inserts MGMN400-M CVD Coated Carbide Lathe Tools

Product Details:

| Place of Origin: | zhuzhou |

| Brand Name: | KIMHOO |

| Certification: | ISO9001:2015/ CQC .IAF. CNAS |

| Model Number: | MGMN400-M |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100PCS |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Inner plastic box ; outside wooden box or as customer's special requirements. |

| Delivery Time: | In stock 3 days,out of stock 35 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 500000 Piece/Pieces per Month |

|

Detail Information |

|||

| Material: | Tungsten Carbide | Usage: | External Cutting Tool |

|---|---|---|---|

| Hardness: | Above 90HRC | Application: | Parting And Grooving Inserts |

| Color: | Black/Gold | Workpiece: | Steel, Stainless, Cast Iron Etc |

| Product Name: | CNC Carbide Inserts | Service: | ODM And OEM |

| Physical Performance: | High Hardness,strength, Wear Resistance | Package: | Plastic Box With Carton Box |

| TRANSPORT: | Negotiable | ||

| Highlight: | carbide insert parting tool,carbide parting tool |

||

Product Description

Description:

1. MGMN400-M series inserts have more economical and versatile double cutting edge.

2. This series of inserts allows multi-function machining.

3. One kind of tool can be used for cutting groove, turning, end face or profile machining, etc., which shortens blade replacement time and improves production efficiency.

Applications:

MGMN400-M series blades have the geometric design of flat cutting edge and high feed processing. The ideal surface roughness can also be obtained through the use of polishing function.Our company has 1.5, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0mm and other full series of slot width cutting blades.

Our Grade :

| K | T | 6 | 3 | 2 | 0 |

| Brand |

Materials

|

Coating | Grade | Process Conditons | Update Materials |

| K=kelite Brand | T:Tungsten Based Cemented Carbide | 0:Uncoating | 1:Steel | 1. Finish | 0:Normal Materials |

| C:Cermet | 6:CVD coating |

2:Stainless steel |

2.Semi-Finish | 5:Update Materials | |

| E:Ceramics | 8:PVD coating | 3.Cast Iron | 3.Rough | ||

| D:PCD | 4.Non-ferrous metals | 4.Heavy Duty | |||

| B:CBN | 5.High Temperature Alloy | ||||

| 6.Quenching Materials | |||||

| 8.Gerneral Procss | |||||

Feature Advantage:

| Quick Response | Inquiry will be replied within 8 hours. |

| High Quality | Well-trained workers and more than 13 years’ experience. |

| Competitive Price | Directly from factory to save your cost. |

| Short Lead Time | Being efficient: 3 days for samples and 10-35 days for bulk orders. |

| Flexibility | Small orders are acceptable for quick delivery and to help you reduce stock cost. |

| OEM | Customerized production according to your drawings, samples or designs. |