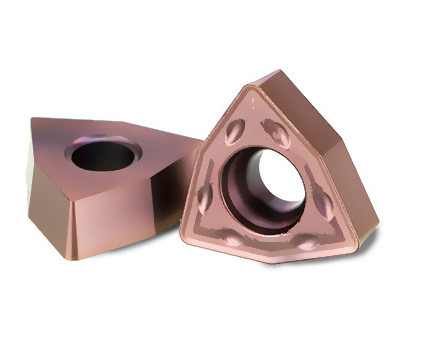

YBG205 Indexable Carbide Inserts SPMG Series SPMG05 / 06 / 08 / 09 /14

Product Details:

Get Best Price Contact Now|

Detail Information |

|||

| Name: | Indexable Carbide Inserts | Coating: | PVD |

|---|---|---|---|

| Sample Order: | Acceptable | Usage: | Metal Drilling |

| Highlight: | pvd coated inserts,zccct carbide inserts |

||

Product Description

| Material: | Tungsten Carbide | Grade: | YBG205 |

|---|---|---|---|

| Coating: | Grey |

Tungeten Carbide Indexable U drill Inserts SPMG Series SPMG05/06/08/09/14 for Hole Making Drilling and Milling

Description:

1. 100% virgin raw material of powder for each insert to ensure you top and stable quality.

2. High technical production line to ensure delivery on time.

3. More than10,000 sets of of molds with various of types, sizes, chipbreakers and coating for customer to choice to meet customers requirements. Also we accept special design to open new mould according to customers drawings and samples.

4. Different packages :different color /brand/size of inner plastic box and outside wooden box .

5. 24 hours on line for sales and after sales service and in time technology supports.

- Center and periphery insert

- Geometries and grades for all materials

- Wiper geometry for best surface finish

- Engineered special options diameter range available

- Available with internal coolant supply

Application:

- High tool body strength enables demanding plunge drilling operations

- Power efficient, productive solution with high metal removal rate

U drilling is an effective method for roughing out cavities. It makes a deeper hole or cavity through repeated axial cuts. Coromant U drill can be used in broad machining conditions.

Max drill depth is 6 x DC for plunge milling in through- and blind holes. Blind holes need to be monitored for chip accumulation and evacuation. Superior deformation resistance and toughness with engineered carbide substrate. It is an excellent choice for medium machining of a wide variety of workpiece materials, particularly stainless steels and high-temperature alloys.

Due to the interrupted cut, a tough grade and a strong geometry is needed. Use grade GC1020 with geometry. For best stability, always use the shortest possible drill. Use internal coolant supply for better chip evacuation. Maximum step-over rate: 70% of the drill diameter. This will provide the optimal cavity-making efficiency without leaving a material core in the cavity.

Specification:

| item name | SPMG Series |

| Place of Origin | Zhuzhou |

| Model Number | various |

| Workpiece | Aluminium |

| Application | Milling |

| Color | Silver |

| Hardness | various |

| Coating | unCoated |

| Material | Tungsten Carbide |

![]()

![]()